Sitting on 35 acres, historic Bear’s Mill is one of the last gristmills available in the state of Ohio. Providing flour since 1849, this water-powered stone grinder continues to make stoneground flour. The mill offers self-guided tours, seasonal celebrations, and local art.

Listed on the National Register of Historical Places, visitors can learn about the workings of a water-powered mill. Built by German immigrant Gabriel Baer, the location is rich with history. Interestingly, the name of Gabriel was documented as Bear, translated in error when he arrived to the United States.

Built using American Black Walnut siding, the interior beams range from 12 x 16 and 50’ long in one continuous piece. The site of the mill was granted to Major George Adams by President James Monroe in 1824. In 2001, the siding was restored to its original condition with the help of the Friends of Bears Mill, a non-profit organization. .

Entering the mill on the first floor, there is a small shop that offers flour produced by the mill as well as local products and kitchenware.

In an adjacent room on the first floor is an additional shop that displays local artwork available for purchase. While there is a permanent collection of pottery created by the miller’s wife, every six weeks, the mill hosts a rotating art exhibit on the final Friday of the month to Monday. Visitors can also meet the artist and purchase their work through the gallery.

Starting at the base of the stairs of the first floor, I began my self-guided tour of Bear’s Mill. While the tour begins on the fourth floor, the first floor is also the where the production of flour begins.

The local farmer would pull up to the entrance with his sacks of grain, ringing the bell to alert the miller. The miller would lower a rope so that the farmer could send his bags up to the miller on the fourth floor.

Weighing in at 100 pounds each, it was much easier for the miller to use a winch and pulley system to bring in the grain to the fourth floor. As a gravity fed mill, the process of producing flour starts at the top and proceeds downward.

Once the grain has been hoisted to the top floor, it is put into a hole in the floor and stored in bins until the grain is ready to be cleaned. During the cleaning of the grain, the kernels will travel up and down the mill through the elevators five times before the process has been completed.

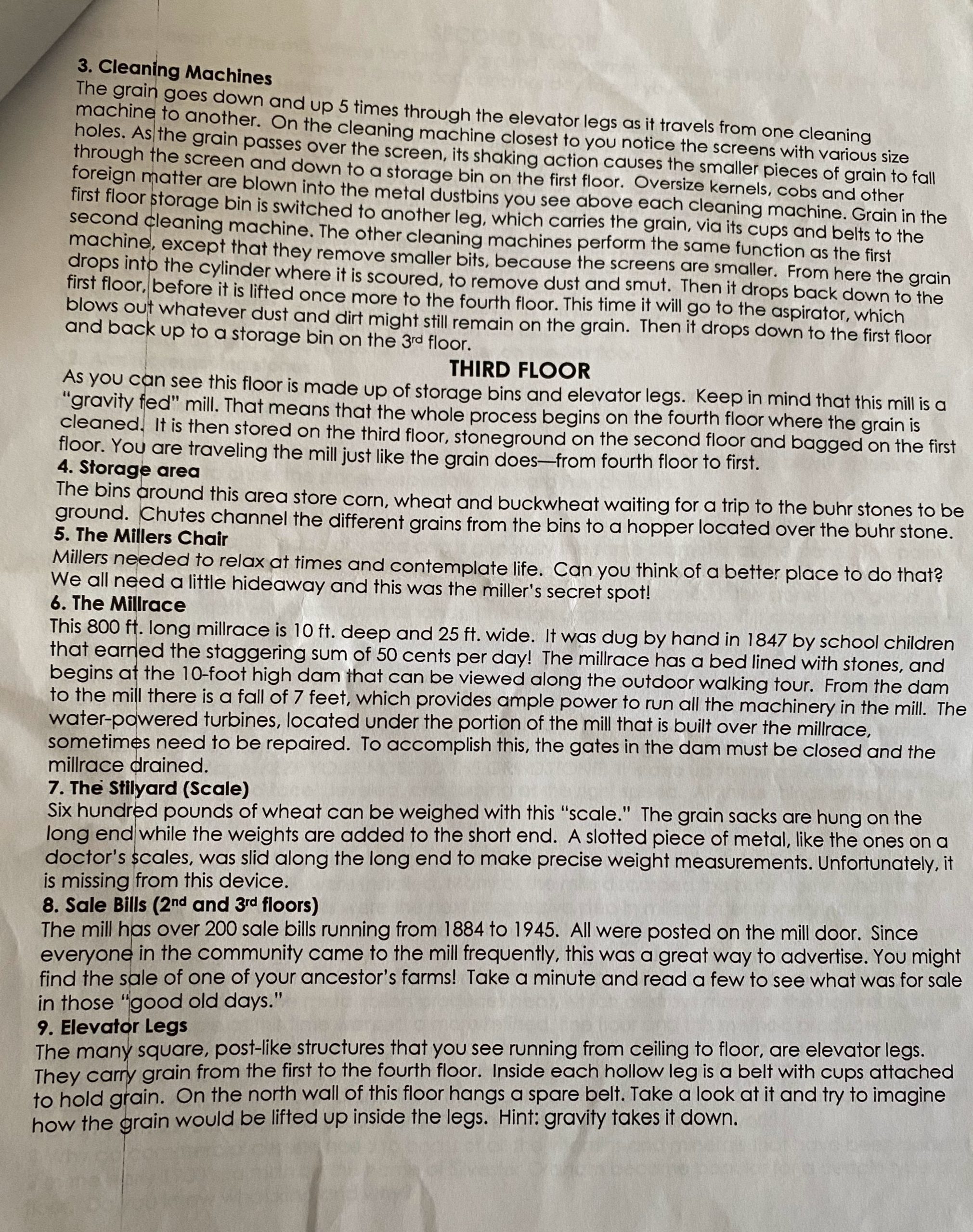

The cleaning process includes the shaking of the grain through screens so that the larger pieces such as cobs, kernels, leaves, etc. are removed. This process is conducted twice until the remains are dropped into a cylinder traveling to the first floor and ready for the next step.

The cleaning process continues as dust and smut are removed from the grain. Once again, the pieces of grain will end up on the first floor but must be moved to the fourth floor so that the grain will be blown by an aspirator so that remaining dust and dirt is removed. Once the grain travels back down to the first floor, it will be brought up to the third floor where the milling process will continue.

In preparation of the milling process, the buckwheat, corn and wheat is stored in bins on the third floor. This floor was also a great place for the farmer to wait until the flour had been ground. Here they would sell other produce they brought along, catch up on local gossip or play games such as checkers or cards.

The milling process begins when the grain is put into chutes channeling the grain towards the hopper located over the buhr stones.

Browsing the third floor, there are some interesting items to include the scale which could weigh up to six hundred pounds of grain, elevator legs and the buhr stones. I enjoyed browsing the authentic Darke County Fair posters as well as the sale bills that displayed the livestock and produce the locals would have been selling.

The French buhr were the most sought after millstones due to their abrasive and porous qualities as the result was a slow grinding process. Have you ever heard the old adage, “Keeping Your Nose to the Grindstone?” During the grinding process, the miller would need to keep watch over the grindstones to ensure that they did not overheat, causing an offensive burning smell.

The buhr stones on display at Bear’s Mill were the original stones that Gabriel Baer imported in 1848 talking two years to eventually reach the United States. Costing $6000 in the mid-1800s, this would be equivalent to about $140,000 today.

Bear’s Mill did not utilize the typical water wheel system but rather used turbines which was a more modern technology of this time. The turbines are approximately 10 feet below the water, working just as they had over 150 years ago.

Exploring Bear’s Mill was such an amazing history lesson and insight into the technology of grain making in the mid-1800s. I was happy that the mill continues to produce various flours and sells it on-site with additional gourmet foods.

Have you visited Bear’s Mill in Greenville? What did you think of the flour-making process? Did you purchase any items from the store? I would love to hear about your experience if you would kindly leave a message in the comments section below. Many thanks for reading about my day trip to Bear’s Mill and wishing you many Happy Travels!

UPDATE: Check out bonus information below!

What to See and What to Do:

Bear’s Mill

6450 Arcanum – Bear’s Mill Road

Greenville, OH 45331

937 548 5112

- Admission Fee: There is no admission fee, but donations are welcome.

- Hours: The mill is open Tuesday and Wednesday from 10AM to 4PM; Thursday thru Saturday from 11AM to 5PM and Sunday 1PM to 5PM.

- Length of Visit: 1 – 2 hours

- Tips for Your Visit: Wear comfortable shoes for hiking. Look for albino squirrels at this park.

Where to Stay:

The Inn at Versailles

21 West Main Street

Versailles, OH 45380

Telephone: 937 526 3020

Where to Eat:

The Merchant House

406 South Broadway

Greenville, OH 45331

Telephone: 937 459 4405

Where to Drink:

Kennedy Vineyard

3911 State Route 722

New Madison, OH 45346

Telephone: 937 273 8381

On a second visit to Bear’s Mill, I learned that there is a scenic walking path that leads towards the back of the mill. Here are some photos from the trail.